|

|

|

Knowing the differences between the various types of sleeving can make it much easier to select the proper Techflex product for your application.

Each type of sleeving has different characteristics and properties, and each type has particular advantages under various conditions.

|

|

| |

Braided

Monofilament |

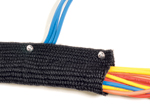

This type of sleeving is produced from single flexible strands (filaments) of polymers or metals. Braided monofilament sleeving generally has the greatest expandability and flexibility of any of the various sleeving types, and is often used when managing bundles of wires over long lengths is necessary.

The wide expandability makes installation over existing plugs and connectors possible, and when properly matched to your application, will provide a secure and protective covering.

Additionally, braided monofilament generally has the widest choices in colors and diameters, making it the preferred choice when Immediate identification of wires or managed bundles is necessary.

Breakouts of individual or multiple wires is accomplished by simply pushing the wires through the sleeving at the desired point along the harness.

|

|

|

|

|

|

|

The wide expandability of

braided monofilament sleeving

makes it ideal for managing

large bundles of wires.

|

By combining varoius types

of polymers in the braiding

process, particular characteristics

can be achieved, such as

slip resistance.

|

Braided monofilament

sleeving is routinely chosen for

use in automotive wire

harnesses for its flexibility,

light weight and ease

of installation.

|

Metal wires can be braided

into expandable sleeving,

producing strong and

abrasion resistant coverings

for hoses and cables.

|

Thicker filaments produce an

extraordinarily strong and

abrasion resistant sleeving

without sacrificing flexibility

or expandability.

|

|

Braided

Multifilament |

The soft, fabric-like look and feel of braided multifilament sleeving makes these products attractive fot their visual appeal, but there are many other advantages to this style of construction.

The full coverage provides complete protection for critical wiring bundles and other components, and the tight construction creates a smooth inner surface that minimizes internal abrasion of delicate wires. Even when installed over large bundles or cables, flexibility is virtually unaffected.

Multifilament sleeving expands slightly for quick installation, but for a tight custom fit, is best installed before any large plugs or connectors are attached to the wires.

|

|

|

|

|

Braided multifilament sleeving

provides full coverage and

protection without sacrificing

flexibility or ease of Installation.

|

Braided fiberglass sleeving

provides thermal protection in

even the most aggressive high

temperature environments.

|

Braided multifilament sleeving

is often selected for use in

wiring harnesses and custom

cable snakes for its soft,

fabric like look and feel.

|

|

Wraparound

Sleeving |

No matter what the construction type (monofilament, multifilament, laminated, etc.) wraparound type sleeving is the most versatile when installation over existing assemblies is necessary. When components cannot be taken apart for management, wraparound sleeving just opens up along the entire length and simply wraps over and around the wires or cable bundle.

Depending on the product and the requirements for repeated access, the split edge can be sealed with either a hook and loop system, an adhesive edge or, in the case of Flexo F6, the edge overlap eliminates the need for any type of closure at all.

Network bundles, workstation cabling, complex harnesses, automotive and marine engine retrofits and robotic welders and assemblers are just a few applications where wraparound sleeving is the economical and servicable choice for a wire, hose or cable management solution.

|

|

|

|

|

|

|

Wraparound Dura-Wrap sleeving

in use on hydraulic pistons to

protect them from sbrasion and

damage in harsh construction

environments.

|

Some wraparound sleeving

can be attached directly to

surfaces as a versatile and

economical wire duct solution.

|

When dissassembly of existing

components is impractical or

impossible, wraparound sleeving

provides a simple and time

saving solution.

|

Sometimes, wraparound is the

only workable solution, such as

in auto or motorcycle customization and renovation.

|

Workstation cables and wires

can be managed easily with

wrparound sleeving, resulting

in a neat appearance and a

safer work environment.

|

|

|

|